My professional growth within UIR project

Vladimir Zhukov, Outotec (Finland) Oy

The idea for geopolymer large scale 3D printing came from Outotec (Finland) Oy (later Outotec) and project application was initiated together with city of Lappeenranta and Lappeenranta-Lahti University of Technology (later LUT University). Outotec also helped to grow consortium for UIR project. Outotec’s role is mainly financing and coordination of initial project plan. Outotec’s vision is that 3D additive manufacturing construction will be soon viable alternative for plant projects. Research focus is recipe oriented with main ingredient being tailings and their future use in construction industry.

My work as academic researcher at the Outotec for UIR project has started in beginning March 2019. The project at that time has already proceeded 1.5 years and many participants cooperated very well. I have started from the literature review in the field of geopolymers and their processing, especially related to 3D printing. In my first teamworking event with different work packages at LUT University meeting in April 2019 during the professional visit of project expert from EU – Kinga Korniejenko. That meeting was very helpful to understand the world of geopolymers research, scope of project, participants and their role, intermediate and expected project results between different work packages.

Another wonderful meeting that I had is project meeting at Apila Group Oy premises where it was possible to see the 3D geopolymer printing at laboratory scale out of tailings material. When visiting Fimatec Oy I saw the bigger scale 3D printer with robotic arm controlled by the operator. 3D printing process was smoothly done, and the results were very promising for the next scale stage. Fine ground mineral tailings seem to be very well suited for 3D printing in larger scale also.

In July 2019 I had pleasure to join warm meeting at the Peter the Great St. Petersburg Polytechnic University to see and compare similar project work with 3D geopolymer printing in other country. Laboratory “Construction of unique buildings and structures” has pilot scale portal printer with operational field 3500x3400x1000 mm and was able to print standard normal size bench from geopolymer. Material feeding to the hopper was manual by operator’s hands and printing nozzle movement was controlled by computer software.

The same time at the Peter the Great St. Petersburg Polytechnic University it was great opportunity to meet key persons from the world leading company in 3D geopolymer printing RENCA RUS – Andrey Dudnikov and Marina Dudnikova. They are high level expert in that field, and it was excellent occasion to discuss about the geopolymer’s issues. RENCA RUS has vast experience in recipe development for the industry. Renca advised us to have virtual meeting with representatives from the Italian company GeoMITS and it was very encouraging for possible cooperation in the current or future projects. GeoMITS has larger scale mixing station for geopolymers, that could be used in full scale.

I got the invitation to participate in the Geopolymer Summer School 2019 in July at Krakow University from the Kinga Korniejenko and was able to visit that event. It was interesting and useful because of combination lectures from the leading professors and practical laboratory workshops.

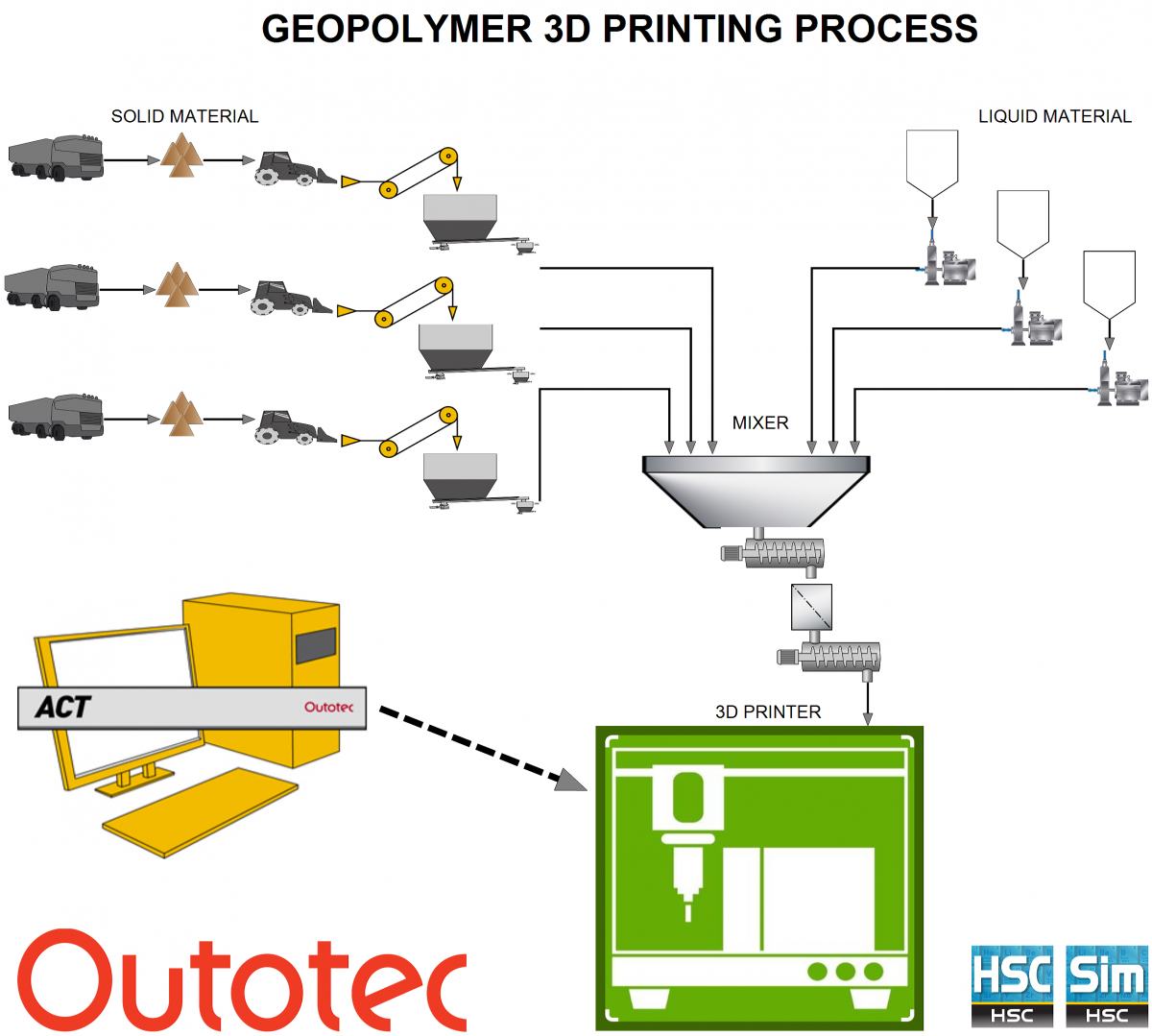

In June 2019 in Outotec Research Center in Pori I had a chance to have a course for learning how to use one of the Outotec product – HSC Chemistry software. My research work and all mentioned above events taught me to do modelling and simulation of 3D geopolymer mixing process in HSC Sim software. In addition, in October 2019, Outotec finalized UIR output O.5.2.1 industrial scale up report. In HSC Sim it is possible to build the model for geopolymer mixing process including such important features like particle size distribution, mineral and elemental composition. Of course, chemical reactions which appears during the mixing can be also described and identified. Outotec continues to develop simulation plant models for new recipes due to the structural changes in recipes.

Comments